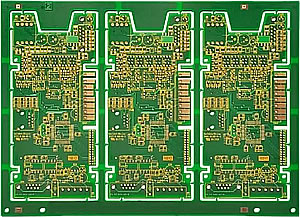

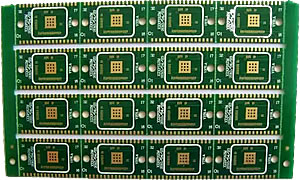

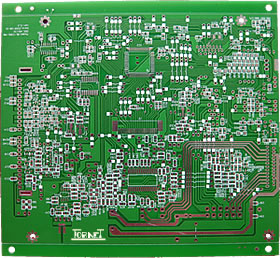

Quality Commitment of PCB

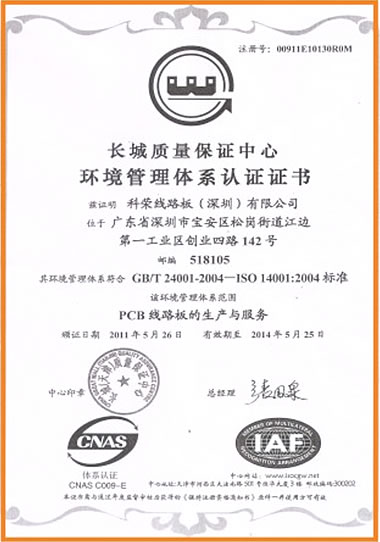

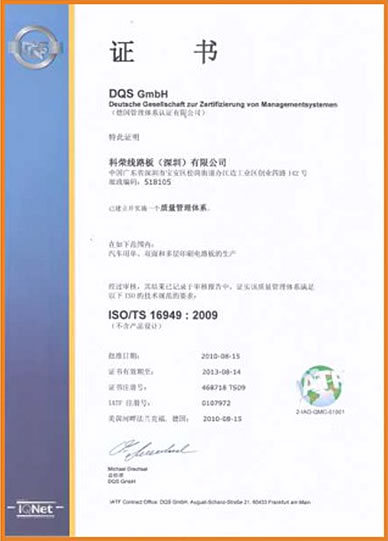

Our factory has been Assessed & Certified by Underwriters Laboratories Inc., (UL) with # E132041 since 1990, Assessed & Certified ISO 9002; 1994 since 1997 and upgraded to ISO in January 2005 Assessed & Certified for TS 16949; 2002 since 2007 and Upgraded to TS 16949: 2009 and ISO9001: 2008.

Our Top Management is committed to make this Facility and ISO 14001:2004 Certified one to support to our customer with all kinds of Rohs finishing surfaces so that we help in creation of “GREEN INDUSTRY” AND A “GREENER WORLD”.

Company Philosophy

Objectives

- To achieve zero defect

- To have zero customer claim

Strategies

- Ensuring that we produce Quality Products

- Competitive Price

- On Time Deliveries

- After-saled Support

- Effective Communication both Internal and External

- Keep abreast of the latest Technologies